TRUNNION BALL VALVES

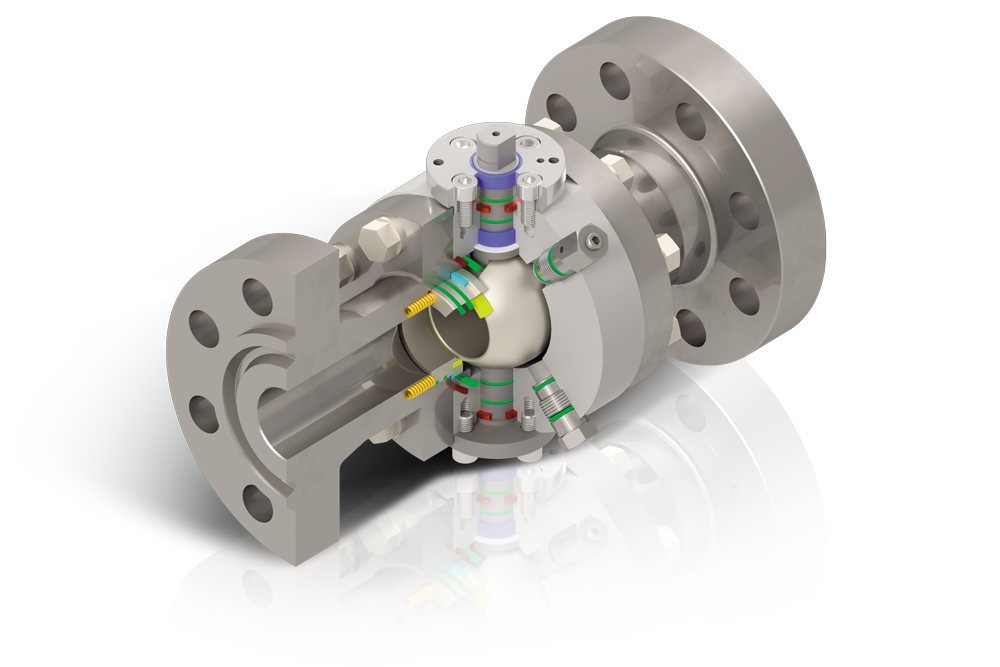

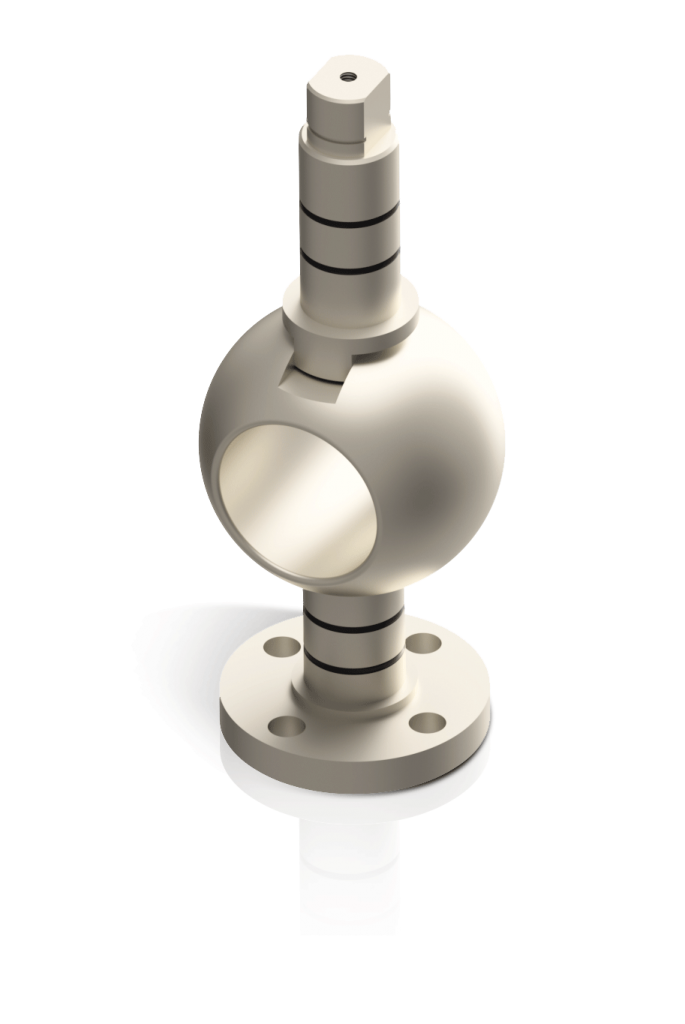

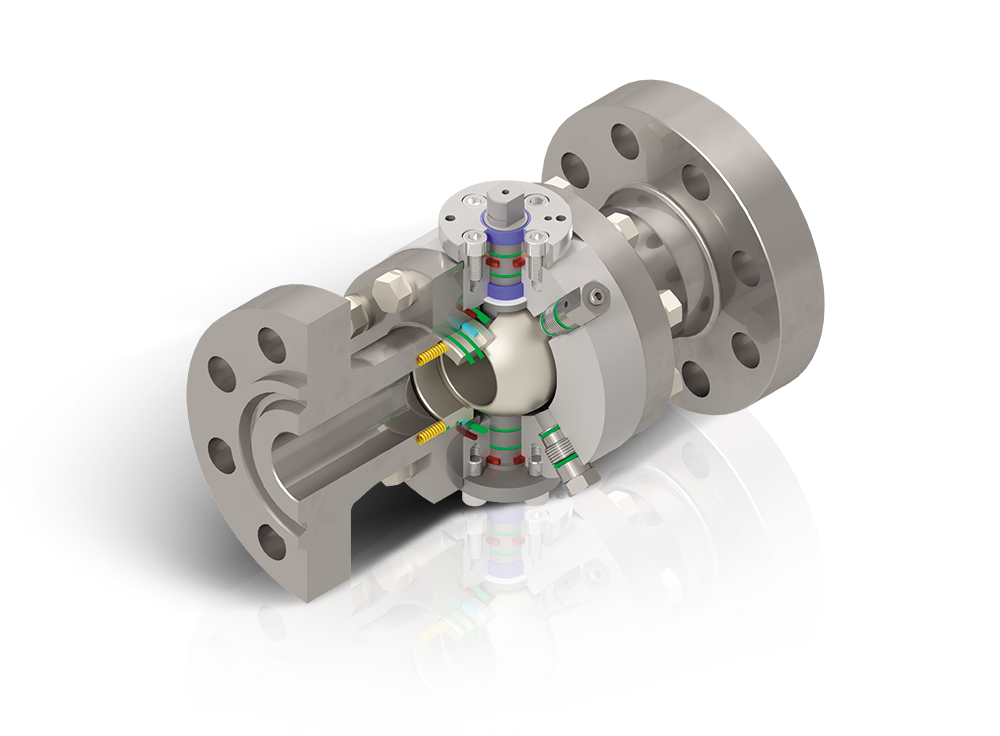

Trunnion mounted ball valves are based on a system that provide a fixed ball and floating seat rings, moving along the valve axis.

The side load given by the pressure acting on the ball is absorbed by the bearings. At low pressure, the sealing on the seats is obtained by the spring action on the seat rings. The more the pressure increases, the more it pushes the seats against the ball.

Starline trunnion mounted valves are available from ½” to 36” – ASME class 150 to 2500 – as well as API 6A 5000 and 15.000 – in several combinations of materials and execution to cover all possible service application from low temperature to high pressure

INDEPENDENT BALL AND STEM

Ball and stem are manufactured in two

separate pieces to reduce the effect of

the side load generated by the pressure

acting on the ball.

ANTI-STATIC DEVICE

All valves are guaranteed for electrical

continuity between all the metal

components type tests are duly

executed and valves are certified.

3 PCS BOLTED CONSTRUCTION

The 3 pcs construction allows an infinite

flexibility in the valve construction in

terms of possible end connection

combination.

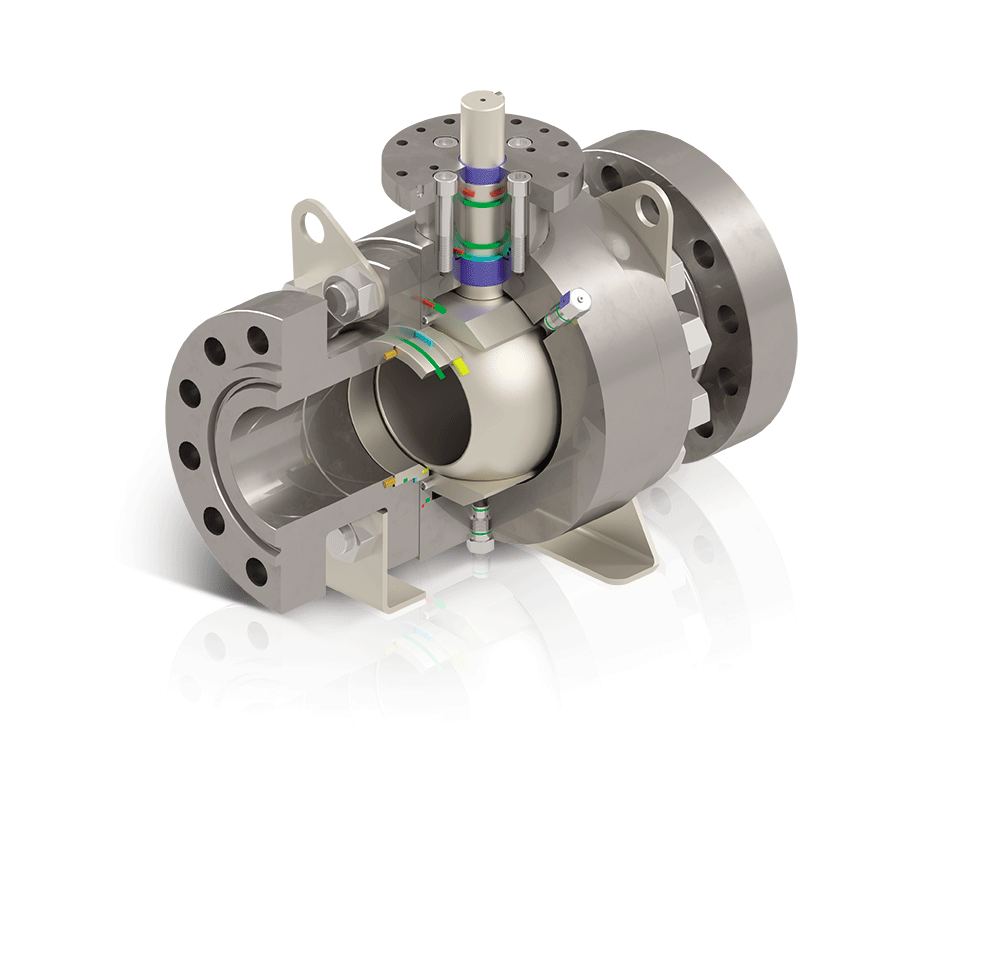

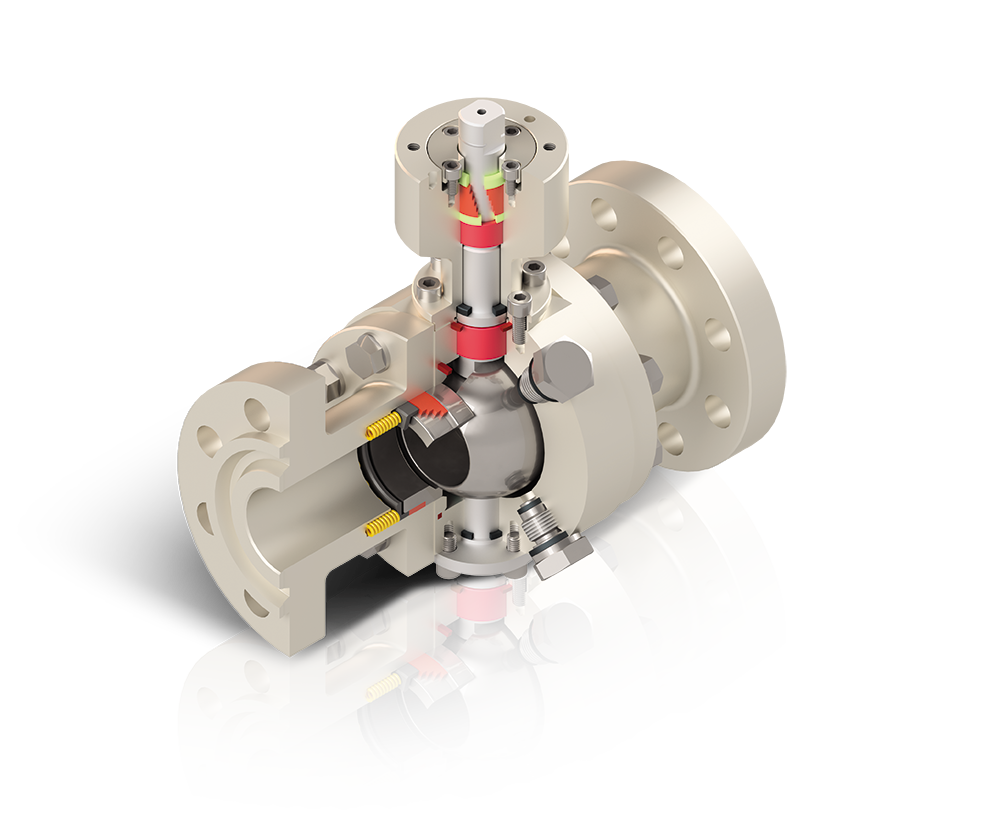

Metal Seated

ABRASIVE SERVICE

Valves designed for abrasive service and for resistance to wearing and abrasive media. This specific execution is using the same basic components of a normal TRUNNION MOUNTED valve and only modify the ball and seat material which are coated by min 150 microns of Tungsten and Chrome.

On request, this valve can be supplied with higher coating thickness up to 400 Microns. The coating treatment is fully certified according to the highest standard requirements.

Starline can guarantee a tightness class according to ISO 5208 RATE A on all sizes and pressure ratings even with GAS TEST.

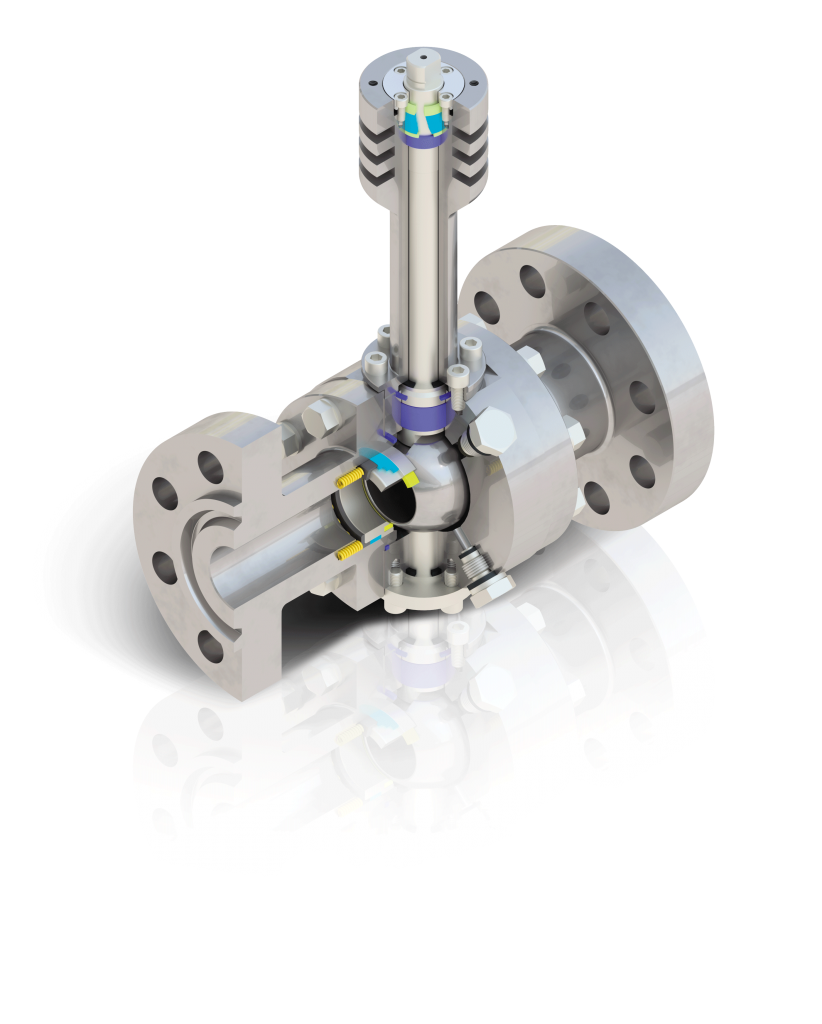

HIGH TEMPERATURE

For operation in temperatures that do not allow the use of resilient material, Starline has developed a specific design for high temperature. Valve is specifically equipped with a stem extension for insulation and is available in many different specific materials to face even extreme temperatures.

Starline can guarantee a tightness class according to ISO 5208 RATE A on all sizes and pressure ratings even with GAS TEST.

LOW TEMPERATURE CRYOGENIC VALVE

Fully designed to cover BS6364 requirements for full tightness in medium and severe cryogenic service.

This execution has been fully tested at -196°. Extended stem length is adapted to the valve size according to BS6364 – thermal fins isolate the stem tightness from the cold temperature.